Apabila kumpulan syarikat kami diambil alih oleh sebuah syarikat petroleum multinasional, keselamatan bukan lagi sekadar prosedur —

ia menjadi satu pegangan dan kepercayaan yang tidak boleh dikompromi.

Standard yang diperkenalkan amat tinggi.

Jauh lebih tinggi daripada apa yang biasa diamalkan oleh industri tempatan.

Dan pematuhan bukan satu pilihan — ia satu kewajipan mutlak.

Antara keperluan utama ialah memastikan semua pembekal dan kontraktor

kompeten, diperakui, dan patuh sepenuhnya kepada standard keselamatan yang ketat.

Bagi kami di Lahad Datu, ini bukan cabaran biasa.

Ia adalah cabaran struktur dan ekosistem.

Lahad Datu bukan bandar industri petroleum seperti Kota Kinabalu atau Sipitang.

Realitinya:

• Pembekal bertauliah sangat terhad

• Rigger bertauliah hampir tiada

• Penyelia angkat (lifting supervisor) sukar ditemui

• Peralatan khas amat terhad

• Jarak jauh dan logistik mencabar

• Kos sangat tinggi

Namun, keselamatan tidak berunding dengan geografi.

Dan ia tidak tunduk kepada keselesaan.

Maka, perjalanan transformasi pun bermula.

Kami tidak bermula dengan ugutan atau menamatkan kontrak.

Kami bermula dengan pemahaman dan pembinaan keupayaan.

Semua pembekal dan kontraktor dipanggil.

Kami jelaskan secara terbuka dan jelas apakah keperluan keselamatan baharu — dan mengapa ia penting.

Kami tidak sekadar menuntut pematuhan.

Kami membantu mereka mencapainya.

Jika mereka tiada pakaian perlindungan tahan api — kami pinjamkan.

Jika mereka tidak tahu di mana mendapatkan PPE yang patuh — kami tunjukkan.

Apabila rigger dan penyelia angkat bertauliah diperlukan —

kami membawa jurulatih dari Kota Kinabalu dan menjalankan latihan rigging dalaman.

Kami menghantar jurutera kami sendiri ke Terengganu —

bukan untuk prestij,

tetapi untuk menjadi penyelia angkat yang diperakui.

Pelan angkatan (lifting plan) rasmi diwajibkan.

Setiap angkatan direka secara kejuruteraan.

Setiap kren diperiksa tanpa kompromi.

Tiada pengecualian.

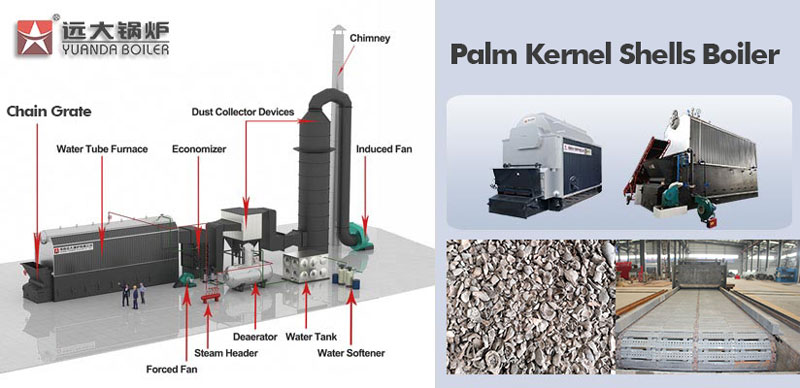

Ada ketika kami terpaksa menggerakkan satu daripada hanya dua kren khas di seluruh Sabah

hanya untuk menjalankan pemeriksaan ketebalan pada cerobong dandang setinggi 42 meter.

Kosnya sangat tinggi.

Logistiknya melelahkan.

Namun kami tidak pernah ragu.

Kerana keselamatan tidak pernah mahal —

kemalanganlah yang sebenarnya mahal.

Tahun pertama amat mencabar.

Kemajuan perlahan.

Tentangan wujud.

Ada yang mengatakan standard ini tidak realistik.

Ada yang percaya ia mustahil dilaksanakan di Lahad Datu.

Namun konsistensi mengatasi tentangan.

Selepas lebih dua tahun transformasi berterusan, perubahan mula kelihatan dengan jelas.

• Pembekal kompeten kini tersedia

• Kontraktor tempatan telah berkembang

• Budaya keselamatan tidak lagi bersifat projek — ia telah berakar

Mereka tidak bekerja selamat hanya apabila bersama kami.

Mereka membawa budaya keselamatan yang sama ke mana sahaja mereka pergi.

Standard tinggi kami menjadi dikenali — bermula di Lahad Datu, kemudian ke seluruh Sabah.

“Above the industry standard” bukan lagi slogan.

Ia menjadi identiti kami.

Reputasi inilah yang menyumbang kepada penerimaan Golden Hat Award pertama dalam syarikat.

Namun anugerah bukan matlamat utama.

Pencapaian sebenar adalah ini:

Sejak akhir 2022, kami merekodkan

Sifar kemalangan.

Sifar kecederaan.

Sifar kehilangan masa bekerja (LTI).

Pekerja bekerja dengan lebih yakin.

Kepercayaan terhadap sistem semakin kukuh.

Pemilikan keselamatan wujud di setiap peringkat.

Dan itulah kejayaan sebenar.

Kerana kejayaan keselamatan yang hakiki bukan trofi atau pengiktirafan.

Bukan audit atau sijil.

Ia adalah apabila setiap insan pulang ke rumah dengan selamat — setiap hari.

Itulah kepimpinan.

Itulah budaya.

Itulah legasi.

#KepimpinanKeselamatan #TransformasiKeselamatan #AboveIndustryStandard #SifarKemalangan

#KecemerlanganOperasi #KeselamatanKontraktor

#KepimpinanKejuruteraan #StandardMinyakDanGas

#KeselamatanIndustri #BudayaKeselamatan

#PenambahbaikanBerterusan #HSELeadership

#MembinaKeupayaanTempatan #KeselamatanSebagaiNilai